New Design for the ESP32 Clock:

The Zyklochron with a Wooden Base

It's hard to believe that three years have already passed since my last Zyklochron update. The clock works perfectly, so I haven't really tinkered with it further. But it was clear from the beginning that the printed base was just a temporary solution, even if it looked good. I always envisioned something made of wood, but I simply didn't have the necessary tools to produce such parts.

A First Attempt with a Router

In the past, I tried it once before, but with completely unsatisfactory results. Back then, I used a router and tried to mill the necessary recesses into the wood with the help of guide rails.

Unfortunately, the result was neither accurate enough nor visually appealing, even though I spent quite a lot of time on it. Somewhat frustrated, I gave up on the idea for the time being, as it became clear to me that something like this was only possible with a CNC router.

New Attempt with a CNC Router

A few more months have passed since then, and recently I finally decided to buy a small CNC router so I could finally realize my original idea. I opted for the Lunyee 3018 Pro Ultra (Affiliate Link), as it's a good compromise between price and performance. For the new design, the basic framework with all the mechanics still comes from the 3D printer, but the casing is now made of wood.

Framework from the 3D Printer

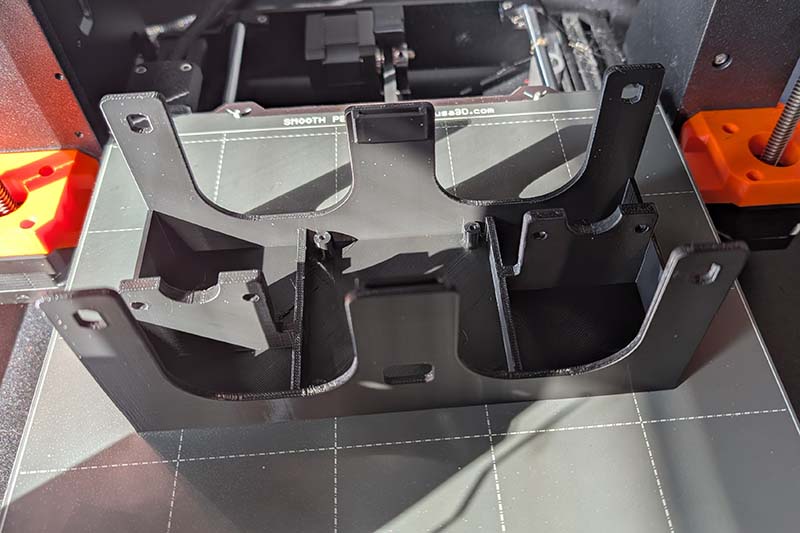

The base has been redesigned from the ground up, leaving only a minimal framework to which the mechanical components are attached.

Since the printed part later has to fit into the wooden casing, accuracy is very important here. I'm now printing with a Prusa Mk4, and as you can see, the dimensions are held very precisely.

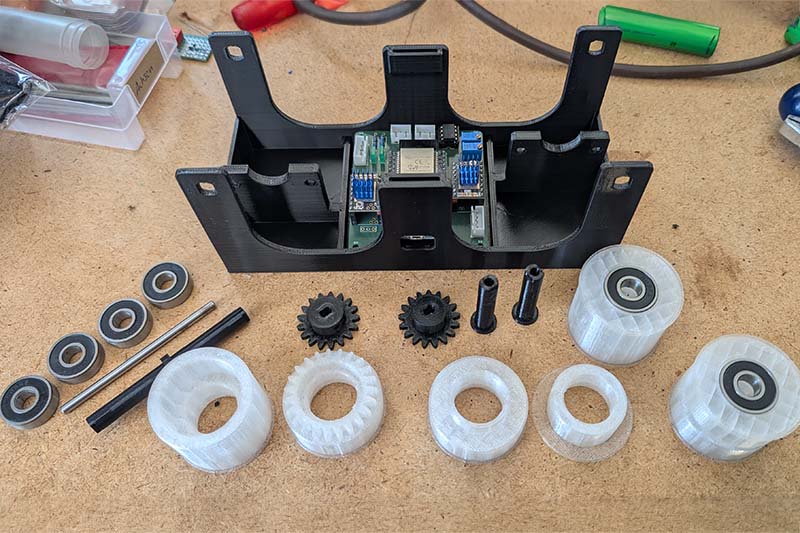

I also reprinted the remaining components, as the old parts were still created with my Ender 3, and the quality of the Prusa printer is significantly higher. This is especially important for the gears, so they mesh cleanly later on. The rollers are now modular, so the sides with the thin rim disc lie directly on the print bed.

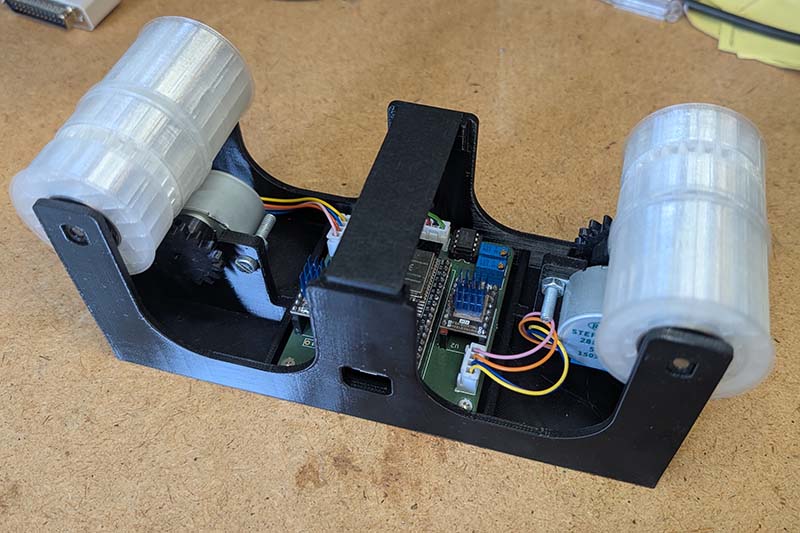

Assembly is now pure routine, as hardly anything has changed in the basic structure. I might eventually replace the ESP32-DevKitC V4 with a modern version, as the new modules all have a USB-C port.

For the new design, I'm again using the proven 28BYJ-48 stepper motors, as they have proven to be extremely reliable over the years and, despite their simple construction, provide sufficient precision for the clock.

Wooden Casing from the CNC Router

For the wooden casing, I deliberately chose cedar wood. It not only boasts a beautiful appearance but is also excellent to work with and gives off a pleasant scent. The basic design remained largely the same; only the inner sides of the wooden base were milled out so that the printed framework can be inserted precisely. Thanks to the CNC router, this can now be done with a precision of one-tenth of a millimeter – a level of accuracy I could never have achieved by hand. As a result, the printed part now sits cleanly and without play in the wood, with no additional fastening required.

The base consists of the front and back, as well as the two side panels. They are made of 6 mm thick cedar wood. After milling, only the holding tabs had to be removed and all edges and surfaces sanded.

In the next step, I glued the four wooden parts together. The empty framework serves to stabilize the individual parts.

Finally, the wood is treated with linseed oil. This significantly enhances the grain and gives it a warm, silky sheen. I also tried teak oil as a test, but the color was too yellowish for my taste.

The wooden casing is simply placed over the internal components at the end. With that, the clock assembly is complete.

And here it is, the new version of the Zyklochron with a milled cedar wood base. In my opinion, the most beautiful clock in the world :-)

Even though the project is completed for the moment, there are still some possibilities for further development: other types of wood, better stepper motors, or a more modern ESP32 board.

Looking back, this project was more than just a new casing for the clock. It was also my entry into the world of CNC. I learned a lot – about cutters, CAM, and the use of clamping claws. Even though I now somewhat master the basics, it became clear to me how vast and complex the topic of CNC actually is. There is still an incredible amount to discover, improve, and understand, but that's exactly what makes it so appealing.

Specifically, the combination of 3D printing and CNC opens up many new possibilities: what was previously only provisional or even impossible to implement can now be produced precisely and reproducibly. Both technologies complement each other perfectly – 3D printing provides functional parts with great design freedom, while CNC milling ensures stability and a high-quality feel.